We pre-stock a large number of frames and expose them to outdoor elements, allowing wind and rain to naturally relieve internal metal stress.

Only frames with fully relieved stress guarantee no secondary deformation after finishing.

Keywords: Label Printing Machine,Intermittent Letterpress Printing Machine ,Flexo Printing Machine ,Screen Printing Machine ,Intermittent Flexo Label Press, Full Rotary Printing Press, Intermittent Printing Press ,Full Rotary Flexo Printing Press , Label Printing Press ,Letterpress Rotary Printing Machine,Label Presses, Printing Press, Roll to Roll Letterpress Printing Machine,Semi-rotary printing Machine ,Reel to Reel Printing Machine ,High Speed Full Rotary Printing Machine ,Label Coverting Machines ,Label Finishing Machines,Die Cutting Machine ,Label Printing & Coverting Solutions,Label Printing Solutions

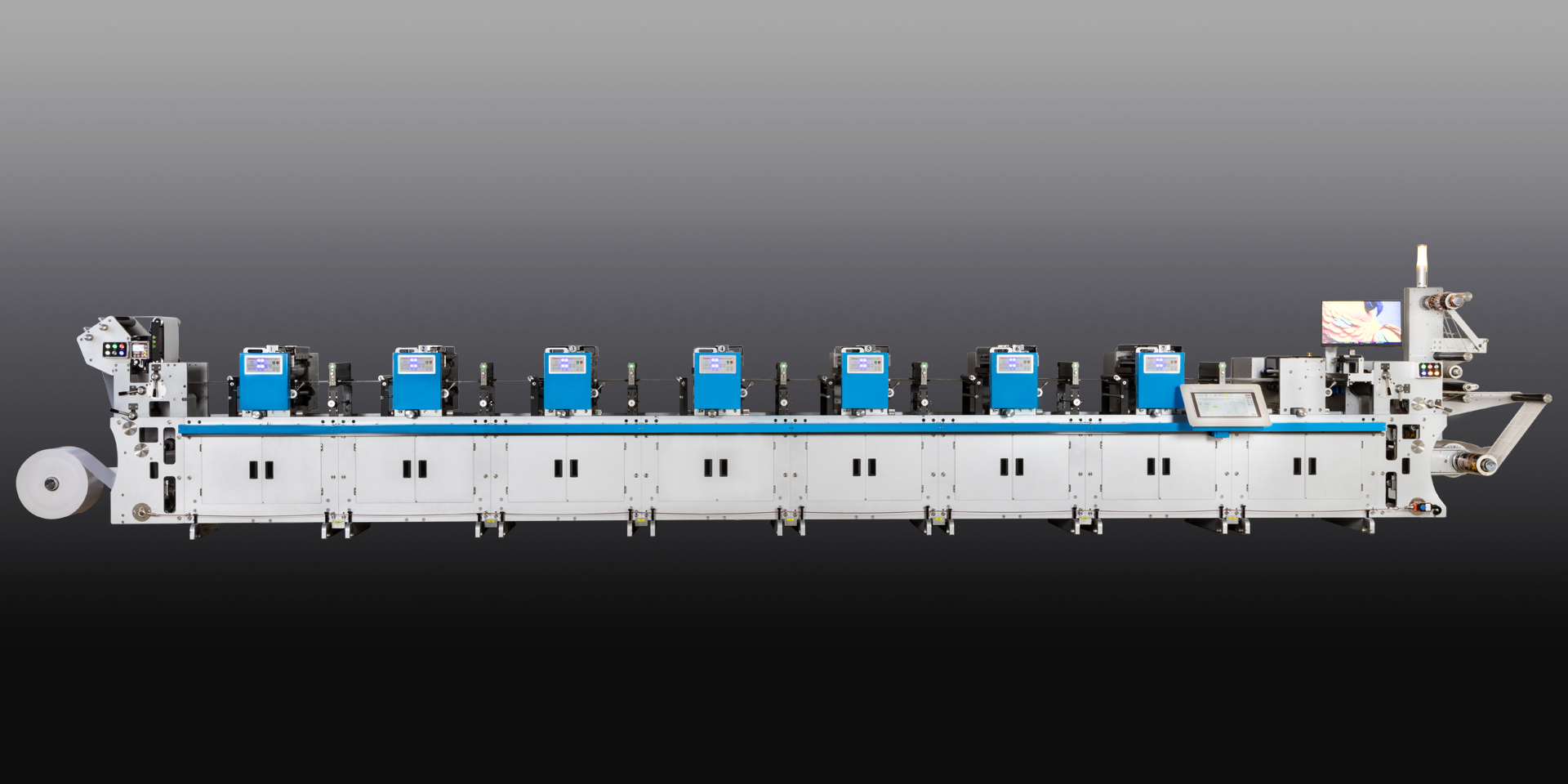

Designed for today’s fast-changing label and packaging market, this printing solution offers exceptional flexibility for short-run, multi-SKU jobs as well as stable performance for medium to long production runs. With a top speed of up to 60 m/min, CS-J380F delivers high productivity without sacrificing print quality or registration accuracy. Fast setup, quick job changeovers, and low material waste help reduce operating costs and improve overall efficiency, making it ideal for converters handling frequent order changes. The user-friendly design allows flexible adjustment of color sequence and process configuration, ensuring smooth operation in demanding production environments. Multiple in-line functions—including rotary die cutting, cold foil stamping, glue-side printing, varnishing, and lamination—can be completed in a single pass, significantly enhancing workflow efficiency and finished label quality. Built on a modular and expandable platform, the machine also supports additional printing units and functional upgrades, offering a future-ready solution that grows with your business.

1. Wide Production Flexibility

Engineered to handle short runs, multi-SKU orders, and medium-to-long production jobs with ease. Ideal for label and packaging manufacturers seeking maximum production flexibility across different applications and materials.

2. High-Speed & Stable Output

Capable of operating at speeds of up to 60 m/min, delivering high productivity while maintaining excellent print quality and consistent performance.

3. Fast Setup, Low Material Waste

Optimized for quick job setup and reduced start-up waste, helping lower operating costs and improve overall production efficiency—especially for frequent job changes.

4. Easy Operation & Rapid Changeovers

User-oriented design allows fast changeovers, simple operation, and flexible adjustment of color sequence and process order, making it well suited for dynamic and high-mix production environments.

5. Integrated In-Line Finishing Solutions

Supports multiple in-line processes in a single production pass, including:

Rotary die cutting

Cold foil stamping

Glue-side (backside) printing

Varnishing

Lamination

This all-in-one workflow significantly boosts productivity, reduces secondary processing, and ensures superior final label quality.

6. Modular Design for Future Expansion

Built with a modular and scalable structure, allowing additional printing units or functional modules to be added as business needs evolve—protecting your investment long term.

Printing colors | 2-10 Colors |

Substrate width | 50-380mm |

Max. printing width | 360mm |

Max. printing area for full rotary | 360mm*419mm |

Max. printing area for intermittent | 360mm*380mm |

Skip distance of intermittent printing | 50mm-380mm |

| Max. unwinding diameter | 800mm |

| Max. rewinding diameter | 800mm |

Caisheng brings 20 years of expertise in crafting top-quality and innovative label printing machines.

20 Years of Expertise in R&D and Production of Label Printing Presses

Four Core Advantages of CAISHENG Printing Machines

We pre-stock a large number of frames and expose them to outdoor elements, allowing wind and rain to naturally relieve internal metal stress.

Only frames with fully relieved stress guarantee no secondary deformation after finishing.

Caisheng boasts an annual production capacity exceeding 200 units.

Our products are developed by industry-recognized experts, backed by strong technical expertise.

With a stable team of technical professionals who have over 15 years of experience, Caisheng ensures exceptional quality and innovation.

Our machines integrate diverse functions—such as printing, die cutting, varnishing, and cold stamping—into a single unit, helping customers save on additional equipment costs and reduce labor expenses.

This multifunctionality also saves valuable space and reduces plant rental costs.

The key benefit is significant time savings in production, enhancing overall efficiency.

Caisheng's unique patented triangular guide rail design guarantees machines remain deformation-free and operate precisely.

Additionally, all commonly used handles and wearing parts are custom-manufactured in-house to ensure superior quality.

Shenzhen Caisheng Printing Machinery Co., Ltd

Address:No.39 Shuitian Road, Tongle Community ,Longgang District, Shenzhen City

Tel:+86-755-8406 3051 Whatsapp:+86 134 2873 3022

E-mail: sales@caishengmachinery.com